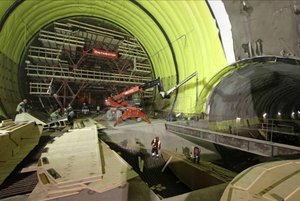

BLANKA COMPLEX OF TUNNELS

This largest tunnel construction project in the Czech Republic (the total length of 5.5 km) is part of the City Circle Road (an inner ring) in Prague. The excavation of all underground spaces was completed in 2011; the removal of the last cubic metre of muck was celebrated on 21st September 2011. The works continued on the final lining, cut-and-cover and cover-and-cut tunnels, including the construction of the intersection between the underground route and at-grade roads.

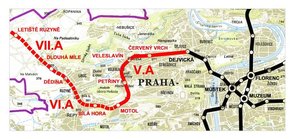

PRAGUE METRO LINE EXTENSION VA

The Line A of the Prague metro is to be extended within the framework of this project from the current terminus in Prague 6 – Dejvice up to the Prague airport in Ruzyne. In the future, the length of the new line will reach 13.47 km. For the time being, the construction of the first part started in December 2009. It comprises 6.2 km of the route from the existing station Dejvická via Červený Vrch and Petřiny stations, to Motol station, which is located next to the largest Prague hospital.

One of the exceptional features of this project is the fact that the mechanised tunnelling technology returns to the Czech Republic after decades, this time at the current worldwide level. Two Earth Pressure Balance Shields (EPBS) manufactured by Herrenknecht AG are deployed on the route. The outer diameters of both machines are 605 cm, with the option of increasing the gauge cut up to 610 cm. The first EPBS was launched in mid-April 2011. The final lining of running tunnels is of the single-shell type. It is formed by pre-cast reinforced concrete segments (5 + 1 system); the inner diameter of the lining is 5.30 m, the lining is 250 mm thick, the mean length of the ring is 1.50 m. The EPBS driving has fully acknowledged itself and, in 2011, advanced absolutely fluently.

TUNNELS ON 4th RAIL TRANSIT CORRIDOR SECTION BETWEEN VOTICE AND BENEŠOV

Part of the rail line modernisation project on the section between the towns of Votice and Benešov is the construction of 5 double-track tunnels; 4 of them are mined structures. The longest one is the Zahradnice tunnel (1044 m), then the Olbramovice tunnel (480 m), Tomice I (324 m) and Tomice II (252 m) tunnels follow. All of them were driven using the NATM.

The fifth structure, the Votice tunnel, is of the cut-and-cover type. It is the holder of several records within the framework of the Czech Republic. Its length of 590 m makes it the longest cut-and-cover rail tunnel with the lining formed by seepage resistant concrete. Even the tunnel lining structure, which is braced at the bottom against the sides of the construction trench, and the tunnel lining reinforcement system are original. The tunnel construction was accompanied by geotechnical problems from the very beginning. They required a change in the method of the construction trench stabilisation.

THE OSEK TUNNEL ON THE 3rd RAIL TRANSIT CORRIDOR FROM PRAGUE TO PLZEŇ

The Osek cut-and-cover tunnel is part of the 3rd rail transit corridor from Prague toward Plzeň, near the town of Hořovice, the village of Osek. The railway track is being diverted in this location to follow a larger radius curve so that the speed limit over the track can be increased to 125 km/h for classical trains and 155 km/h for trains with tilting bodies. The tunnel is 324 m long and the curve radius is 750 m.

The “false” primary lining technique was used during the construction. The self-supporting reinforcement consisting of lattice girders and mesh was installed in the construction trench. Subsequently a layer of shotcrete was applied to the steel structure, forming a concrete shell. The final lining formwork was pushed under the shell. The final lining casting blocks were 12 m long.