A lack of space in built-up areas and a continuously increasing awareness of the environment have made the use of underground space an attractive option. Technical innovations and public opinion have also contributed to this trend. Only a few decades ago, underground facilities were generally regarded as gloomy and unsafe places and not appropriate for the public. Today, underground space is considered as an essential part of the built environment. Not only the sub-terrain traffic, energy, and technical facilities have shown their superiority compared to conventional solution on the surface. Even leisure-time activities have proved to be suitable to be placed underground. 1

The Finnish power industry might be the first in the world to accomplish the final disposal of highly radioactive waste. The construction of the repository for spent nuclear fuel will start around 2015, and the target is to begin disposal operations in 2020. The in-depth research related to the design of the repository has gathered a large amount of knowledge that is useful in the design of underground construction for different purposes.

Geologically, Finland belongs to the Baltic Shield. The bedrock represents the oldest rocks of the European continent, often covered by a thin layer of very young and loose glacial sediments. The rock is generally of good quality and requires only modest rock support, making the underground construction costs reasonable. Such bedrock conditions suggest a good potential to utilize the underground space for various activities. In addition, the mineral resources of the Finnish bedrock are significant, and they had been utilized by underground mining already in the sixteenth century.

The population of Finland is small, and the societies of rock and mining engineers interact frequently. Collaboration already takes place in the university, where mining and rock engineering students are studying side-by-side. Co-operation has supported the development of both sectors, and innovations have contributed to a significant global impact on underground technologies.

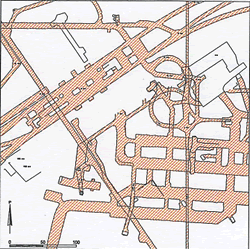

Underground master plan

In Helsinki, underground rock spaces have been put into good use for a long time now. An ”underground world” of many layers of technical maintenance, traffic, and private operations has developed underneath the city. The network has been built one project at a time. The city co-ordinates the whole, ensuring that there will still be space for important developments in the future, and that underground projects situated close to each other could be fitted together. The underground master plan has been designed for managing this whole. 2

Building underground has significantly increased in Helsinki. We have good rock and skilled experts for implementing these rock construction projects. Ensuring the economic foundation and maintenance of the operations situated in the center requires building underground. The business center has become denser, as spaces for technology, traffic and maintenance have been partially situated underground on as many as four levels. The companies benefit from each other and the earth surface has been freed for business operations and pedestrians, for example. Distances for pedestrian and bicycle traffic become shorter and use of public transportation and transfer connections improve.

The pedestrian zone in the business center of Helsinki is a good example of a successful and functional pedestrian zone. The underground maintenance street for the center will keep Aleksanterinkatu and its cross-streets clear of maintenance traffic also in the future. Underground building also frees property for central operations. The center becomes denser and its operational structure more versatile. Simultaneously, the synergy benefits different operations and economic well-being increases. Underground infra, power stations, energy supplies and pump stations bring functional security and safety that even on an international level is in its own class, and makes it possible for even the most delicate maintenance operations to be located in Helsinki.

Environmental Impact Management

The starting point for underground construction is always a secure construction without causing any damage to the environment, which includes both developed (urban) and natural environment. 3

Urban environment

Designing an underground construction site in a densely built urban environment is often challenging. Especially in city centers there are underground facilities situated on several levels.

The starting point for the design is to, among other things, determine the precise location, structures, and possible safety distances of these facilities. The more densely there are underground facilities in the area under design, the more challenging it is to, for example, model the rock’s behavior when constructing new facilities.

On the other hand, construction experience and research information on near-by facilities offer extremely important source material about, for example, the rock conditions in the area.

Geology

Managing the environmental impacts of an underground construction site is based on extensive knowledge of the surroundings. Being familiar with the area’s land and bed-rock conditions is a key factor when compiling programs for managing the environment. Initial geological data is acquired from different map materials, ground survey information, building foundations, and especially from on-the-spot visits. Based on this information, informative data is compiled for any given purpose of use.

Managing the environmental impacts of an underground construction site is based on extensive knowledge of the surroundings. Being familiar with the area’s land and bed-rock conditions is a key factor when compiling programs for managing the environment. Initial geological data is acquired from different map materials, ground survey information, building foundations, and especially from on-the-spot visits. Based on this information, informative data is compiled for any given purpose of use.

Based on the initial geological data, a geological interpretation of rock properties, among other things, is made over the area, which provides source information for rock mechanical modeling. In addition, the groundwater conditions in the area are determined and the risk areas where depressions caused by the groundwater’s lowering are possible are investigated for the environmental management programs.

Rock mechanics

In the present-day, increasingly challenging underground rock engineering projects, rock mechanical design plays a critical role. As rock engineering skills and knowledge grow, new kinds of structural solutions can be found and ever more complicated projects can be executed. Based on rock mechanical design, the constructibility of different facility alternatives can be compared, the impact of construction on environment can be studied, and the possible problematic areas can be focused on in time, among other things, thus prolonging the operational life of the facility.

With the help of rock mechanical modeling, we strive after simulating numerically the behavior of the rock mass, affected by changes in load and in environmental conditions. In urban construction sites, this often means primarily taking into consideration and limiting displacements and deformations caused by the excavation of underground spaces and by the removal of rock mass as a part of the design project and dimensioning solution. In addition, with the help of rock mechanical analyses, damage prediction for critical structures are compiled.

The reliability and level of precision of rock mechanical analyses are mainly dependent on the sufficiency of geological research data and other source information as well as on the correct interpretation of the data, which is why the local conditions must always be researched by professionals, thoroughly and extensively. With the help of sufficient source data and the right modeling tools, it is nowadays possible to simulate structurally very complicated excavation entities with complex duration.

Environmental risk analyses

Before the construction work can be begun, the possible risks and environmental impacts caused by excavation have to be found out. Based on the research done, a preliminary risk assessment of excavation vibration is compiled along with a management program for groundwater and depressions. The need and extent of rock mechanical monitoring is determined by the rock mechanical model made of the site and by the damage predictions.

In preliminary risk assessments, the equipment and functions most important and most vulnerable to excavation are taken into consideration. For example, in the design phase of Kamppi Center, the metro tunnel played an extremely important role, as the feasibility of the site and excavation methods were considered. During the preliminary assessment phase, trial blasts in diamond core drilling holes are often made in order to examine the rock’s vibration transmittance in the critical areas with regard to excavation.

In the excavation risk analysis, the vibration-sensitive equipment and functions, such as computer and hospital equipment, in the surroundings of the planned excavation site are covered. The extent of the risk analysis is proportioned sufficiently according to the quality and duration of the excavation work and to the site surroundings.

The function of risk analysis is to serve as grounds for calculation during the competitive bidding phase and as rules during the excavation work. As regards the building developer, risk analysis is the design document that considers the environmental impact of excavation work and defines the limits of excavation in order to conduct it economically and without endangering the environment. The excavation contractor uses the information and boundary values in the risk analysis for scheduling and as source information in blasting design.

The risk analysis determines the extent and conduct of structure inspections preceding excavation, protective measures for sensitive equipment and objects (for example computers and pieces of art) to be taken before excavation, and at least preliminary places for vibration measurement points. In addition, the risk analysis determines boundary values for the intensity of excavation vibration allowed as regards structures and equipment and guides in following the measurement results.

Environmental impact monitoring

Vibration monitoring

Risk assessment during construction is mainly done by following and analyzing the measuring results of excavation vibration. When necessary, intermediate inspections are made and for example plaster bridges can be installed, if structures are thought to be moving and fracturing – with the help of these methods, ascertained information on the impact of excavation vibration on structures can be acquired as early as possible during construction.

Vibration is monitored with vibration meters, or seismographs, which have been installed in the surroundings of the construction site in places critical to vibration. The measurement results from the vibration meters are often transmitted in real time to an online result service or as a text message into a cell phone.

Groundwater and subsidence monitoring

Water inflow into excavated spaces can lower the groundwater table in stand pipes. This can cause the soil to sink, wooden foundations to decay, or ground supported structures to be damaged. The purpose of groundwater monitoring is to actively react to the ground water lowering, so that possible damages can be avoided. The monitoring is often conducted before and during construction as well as during use. Consequently, the possible environmental impacts caused by construction can be detected during every construction phase.

Rock mechanical monitoring

Rock mechanical monitoring includes measuring the movements in bedrock and engineering geological mapping of rock quality during excavation. The results are constantly being compared with a rock mechanical model compiled beforehand and with calculated displacements. Based on the monitoring, grouting and reinforcement designs are also revised.

Noise, dust, and radon

The implementation of the boundary values set for noise is monitored during construction on site with measurements, at the very least every time that the focus of the site or the working method changes significantly. The boundary values and the objects to monitor are determined by the environmental offices of each municipality and city.

Environmental impacts caused by dust can be reduced, for example, by binding the dust during drilling with a dust collecting system and during loading and transport with the help of water. Dust measurements can be conducted as the need arises.

The radon concentration in rock spaces is monitored with measurements during construction according to a separate monitoring program when excavating in areas defined by the Finnish Radiation and Nuclear Safety Authority (STUK). The boundary values for radon concentration are determined by STUK.

Environmental damages of a project

Contractors and building developers have liability insurance in case of damages. The amounts of insurance are determined by the risks of the construction site. In smaller sites, most excavation contractors have an annual policy.

When suspecting an accident or damage, people in the surroundings of a site contact the site’s representatives, in which case investigations are started. Damage reclamations are investigated and documented. If excavation work is found to have caused the damages, a compensation or repair proceedings is agreed upon.

Compensation procedure

Fairly few accidents and damages occur during excavation work in relation to the amount of on-going construction sites and their being located in residential, business, and industrial areas. Usually, the damages estimated to be caused by excavations are cosmetic by nature; serious structural damages occur very rarely. Suitable procedures are predominantly a financial compensation and damage reparations.

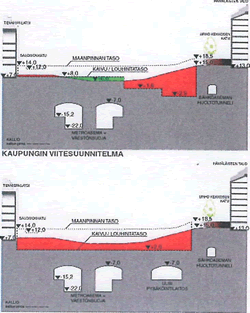

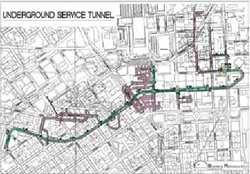

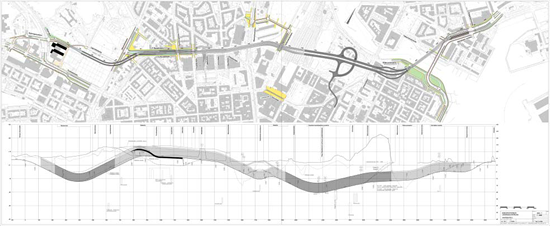

Central service tunnel

The idea of an underground central service tunnel through the city center of Helsinki dates back to the late 1970’s, when the very first drawings were sketched. However, the time was not fruitful for the realization of a tunnel until the first years of the 2000’s, when both public and private sector found each other in the vital question considering the future of the city center. 4

The city planning process was carried out with co-operation between city officials and private sector in order to achieve the best possible solution in developing the central area of the downtown Helsinki. The main goals in the development of the city center area are among others

- to keep the central area viable in the future

- to keep the central area commercially attractive

- extend the pedestrian zone in the city center

- decrease traffic and and congestion in the streets

After several phases the line for main service tunnel was set from Ruoholahti to Kluuvi. The city plan for the service tunnel was accepted by City Council in the year 2005. The city plan for the enlargement of the Stockmann department store was accepted in the same year and the city plan for the City Center shopping was accepted in 2006.

Along the service tunnel there are many other underground facilities which are connected to the service tunnel

- Kamppi Parkki – parking facility

- Block “Pyy” service facilities

- Mannerheimintie – parking facility

- Stockmann service facilities

- Rautatalo service facilities

- Electric substation

- Block “Gaselli” service facilities

- Service facilities for Kämppi shopping center

The service traffic for the main commercial blocks in that area loaded heavily the street network. When the service traffic tunnel was completed the service traffic disappeared from the busy Keskuskatu and allowed the expansion of pedestrian zone in the city center.

Private cars are allowed to drive along the service tunnel to the parking facilities.

Underground Service Tunnel (KEHU)

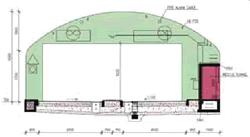

KEHU tunnel consists of two different portals, one from the west for all vehicle and one from the east for service transport only. The total length of the tunnels is c. 2 km. The tunnel cross section is about 110 m². The maximum gradient of the tunnel is 7%. The tunnel has been designed for 12 m long vehicles. The design speed is 40 km/h. The construction costs are about 90 MEUR.

KEHU tunnel is composed of the main tunnel, six technical rooms (appr. 50 m² each) and ten shafts to the surface. There are also about 20 connections to other underground facilities. When considering the strict requirements by the authorities the tunnel system can be regarded as a very complex system.

To meet all the requirements set for the work, the technical solutions used in the tunnel are a combination of the technique used in normal traffic tunnels and underground facilities. In the traffic control system all the driving connections to other adjacent underground facilities is also taken into account. The traffic control system is controlled from Jyväskylä, 300 km away from Helsinki, where the control room of the tunnel is located. In case of emergency the fire alarm cable directs the orders to other systems: fire protection system (Hi-fog), cameras and traffic control.

To meet all the requirements set for the work, the technical solutions used in the tunnel are a combination of the technique used in normal traffic tunnels and underground facilities. In the traffic control system all the driving connections to other adjacent underground facilities is also taken into account. The traffic control system is controlled from Jyväskylä, 300 km away from Helsinki, where the control room of the tunnel is located. In case of emergency the fire alarm cable directs the orders to other systems: fire protection system (Hi-fog), cameras and traffic control.

When considering rock mechanics, the most challenging section was the crossing of the crushed zone of Kluuvi area. Also the groundwater level was strictly observed by the authorities, no decline of the water level was allowed due to the tree props of some buildings in the city center. In the tunnel the first underground traffic circles have been introduced.

Stockmann department store with Mannerheimintie parking facility

Stockmann’s Helsinki department store is the largest department store in the Nordic countries. First plans and feasibility studies for renovation and enlargement of the department store were carried out in 2001–2003. Main drafts in accordance with city planning process were completed 2003–2005 and the decision to start the project was made in December 2005. Excavation works started at the beginning of February 2006 and the project was completed in November 2010.

The underground parts of the project consisted of:

- The logistic operations servicing the department store and Academic Book Store were transferred into the caverns excavated 30 m below the store building

- Total transformation of former service and parking floors under the department store to the “Stockmann Deli” food department and personnel facilities

- Improvement of heating and cooling, ventilation, lightning etc. technical systems

- New facilities and commercial space under the Keskuskatu and transforming the Keskuskatu to a pedestrian street

- The new underground parking cavern under Mannerheimintie for 600 cars replacing those 200 places situated in the lower floors of the store.

As the result of the enlargement project approximately 10,000 m² new retail space was created and the total retail space is now 50,000 m².

Total volume of the underground service facilities is ca. 65,000 m³ including the open excavation works in Keskuskatu area. The largest span is 27 m in the main service hall and the largest height is 13 m. There are 15 shafts connecting underground facilities to the store building.

It was required by the management that all the construction works must be carried out by minimal disturbances to the operations of the store. This led to the innovative protective walls, under pressurizing all the working sites connected to the public and department store employee facilities, customer information procedures on blasting times, working during nights and weekends, etc.

The new car parking facility for 600 cars was excavated into the bedrock under Mannerheimintie, the main street of Helsinki. The parking facility consists of two 160 m long and 17 m span hall, the total volume is ca. 160,000 m³. There are three parking floors, 200 cars each.

The height of the cavern varies between 12–14 m. The Central service tunnel goes underneath the parking halls and the total height of the cavern in that area is 20 m.

There are two access routes into the parking cavern. For the traffic from Mannerheimintie there is about 240 m long route to the upper level of the cavern, about 30 m below the street surface. From west the route is about 800 m long and goes along the service tunnel to the lower level, about 37 m below the street surface.

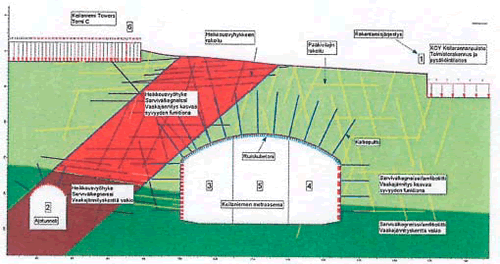

Underground repository facility for nuclear waste

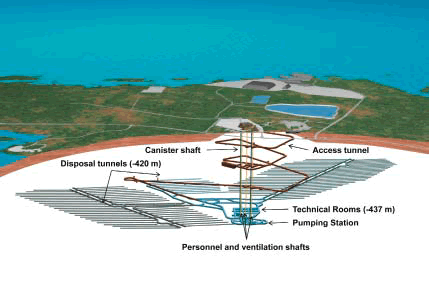

Studies into the geologic disposal of spent fuel have been carried out in Finland since the 70´s. The site selection research program for a deep repository for spent nuclear fuel was commissioned in 1983 by a countrywide survey. Field investigations, aiming at the selection of the repository site, were started in 1987 on five candidate sites. The site selection program was concluded in the selection of Olkiluoto site in 2001. 5

The geologic disposal of spent fuel from the Finnish nuclear power plants – Loviisa 1 and 2, Olkiluoto 1 and 2 and later Olkiluoto 3 and 4 – will be executed by Posiva Oy, a company owned jointly by the two nuclear power producers Fortum Oyj and Teollisuuden Voima Oy. Preparations for nuclear waste management were started already in the 1970s when the first power plants were still under construction. In 1983, the Finnish Government confirmed a target schedule for nuclear waste management, in which the construction of the disposal facility was scheduled for the 2010s and the start of actual final disposal for the year 2020.

Potential sites for the disposal of spent fuel were screened in the 1980s, followed by detailed site investigations in the 1990s and an environmental impact assessment in late 1990s. In 1999, Posiva submitted an application to Government for a Decision-in-Principle to choose Olkiluoto as the site of the final disposal facility. Finnish Government issued a Decision-in-Principle (DiP) in favour of the project in December 2000. Based on this Posiva continued to investigate all important characteristics of bedrock at Olkiluoto and started to design the final repository.

ONKALO

The disposal project has progressed to the implementation stage – constructing an underground characterization facility, named as ONKALO, at Olkiluoto. ONKALO is being used to obtain further information to plan the deep repository in detail and to assess long-term safety and construction engineering solutions. ONKALO enables final disposal technology to be tested under actual, site-specific conditions. ONKALO is not intended solely for research premises, but has also been designed to serve as an access route to the repository when constructed. ONKALO will take about 10 years to complete. Construction is scheduled for 2004–2014 and investigations will be made from the start of construction in conjunction with excavation. Once ONKALO has been completed, work will start on building the encapsulation plant and final disposal repository after the final construction license has been given in 2014.

The site characterization program developed in early 1980s already included the assumption that an underground rock characterization facility would be required at the site confirmation stage to allow a detailed repository design to be developed and the preliminary safety assessment to be produced.

The plans of the underground facility were realized after issuing the Decision-in-Principle. A decision was made to excavate the underground rock characterization facility, ONKALO, at Olkiluoto. The approach adopted was that ONKALO facility shall be constructed in such a manner that it allows further characterization and research work to be carried out without jeopardizing the long-term safety of the repository site. In addition, it should be possible later to link ONKALO to the repository so that they are integrated.

The main characterization level in ONKALO is at the depth of some 435 m below the sea level. The inclination of the tunnel is 1:10, which means that the length of the access tunnel will be approximately 5 km. The total length of the tunnels and shafts will be about 9 km. A total of 420,000 m³ of rock will be excavated. The site preparations for the facility were started in 2003 and the actual excavation work began in September 2004. The tunneling work is carried out by traditional drill & blast techniques. Raise boring method has been used for the vertical shafts under construction.

By the end of January 2011, the excavation of ONKALO had proceeded 4,600 m to a level of -435 m. The excavated tunnel meets the specified quality requirements, the management of leakage waters being one of the most significant requirements.

Underground characterization and research

A program for the underground characterization and research (UCRP) to be carried out in ONKALO has been established. What Posiva aims at achieving with the activities proposed for ONKALO is, that the general suitability of the site will be demonstrated. It is only with such confirmation that it will be possible to proceed to the application for a construction license for the repository. The program during the tunneling stage includes mapping of the tunnel faces, drilling of pilot and characterization holes with subsequent rock mechanical, geological, geophysical and geohydrological studies, hydrogeochemical sampling and measurements, determination of fracture and flow data plus various rockmechanical tests and measurements.

Investigations in ONKALO started in September 2004 at the same time with the excavation work by geological mapping of the tunnel roof and walls. Probe holes, which are core drilled boreholes inside the tunnel periphery, make possible to do various borehole investigations during the excavation work. From the probe holes flow measurements are made and the results are used in the grouting planning, and later also in modeling.

Long term experiments need to have a place for the set up in the tunnel. For that purpose investigation niches and specifically for demonstrations designed tunnels are planned to be constructed in 2011. The first experiments made in tunnel have been rock stress measurements and small-scale hydrogeological interference tests. These tests have been followed with geochemical and geo-microbiological studies.

Because the construction of ONKALO and later the disposal facility will affect the surrounding rock mass, a monitoring program was established. The main aim is to observe possible changes in the host rock and obtain information on the responses of the host rock to the excavation. The results of the monitoring are compared to the baseline values presented in 2003.

All the data achieved with different investigation methods will pass several modeling steps. The interpretation and modeling of the field investigations data aim at building a consistent picture of the site.

Rock mechanics studies

The aim of the Olkiluoto site conforming studies is to verify the present conclusions of the site suitability, determinate and identify the rock volumes suitable for repository space and characterize the target host rock for repository design, safety assessment and planning of the construction work. Rock mechanical information is needed to design a safe underground environment but on the other hand underground laboratory is needed to acquire more detailed rock mechanical data, like reliable state of stress information.

Rock mechanical studies are planned to be conducted in the so called main characterization level. Some of these experiments may continue even years to get estimates for long time behavior of the bedrock. Based on the rock mechanical information gathered so far rock mechanics analysis will be planned for the main characterization level of 435 m in the ONKALO. The objective of the analysis is to evaluate the mechanical state of the facilities (tunnels, technical caverns etc.). The rock mechanics analysis will give useful initial information for the repository design and then support the construction license of the repository.

Traffic goes underground

Up to the beginning of this century, metro was the only major underground transportation infrastructure in Helsinki. In addition to that, there was a short street tunnel, short bus tunnel and several underground parking garages in the inner city. 6

During the first decade of this century several underground transportation projects were constructed:

- Eliel Saarisen tie bus tunnel and interchange with commuter trains at Huopalahti station (2001)

- Extension of existing bus tunnel and two major bus terminals in Kamppi (2005)

- Tunnel for service traffic and traffic to two new underground parking garages in CBD (2009–2010)

- Short street tunnel in Hakamäentie (2009)

Currently, there are several underground transportation projects that are under construction or planning phase in Helsinki.

West Metro

Extension of the existing metro to the west is under construction both in Helsinki and Espoo. The construction was started in November 2009 in Helsinki and the traffic is planned to start at the end of 2015.

The length of the new metro line is 13.9 km and there will be 8 new stations: two in Helsinki and six in Espoo. There will be two parallel tunnels going underground for the entire length of the track. The cost estimate of the project is 713.6 MEUR (in 2007). The state is going to finance 30%. The rest is financed by the two cities, Helsinki and Espoo, according to the actual costs at their territory.

Paloheinä Bus Tunnel under the Central Park

Paloheinä Bus Tunnel is a part of the new regional transverse bus line called Joker 2. The length of the tunnel is about 1.3 km and it will be constructed under the Helsinki Central Park. The cost of the tunnel is estimated to be 33 MEUR. The construction is going to start in late 2011. The operation of the new Joker 2 is planned to start in 2014.

East Metro

A new area of 30 km was incorporated into Helsinki from the municipality of Sipoo and the City of Vantaa in the beginning of 2009. The municipalities Helsinki, Vantaa and Sipoo are currently preparing a common master plan for the area of 45 km² to the east of the previous eastern border of Helsinki. In the future, the master plan area is planned to house 50,000–80,000 residents and employees in total. The public transport system in the area is planned to be based on the extension of the metro from the other eastern end station Mellunmäki.

The length of the metro extension is about 9,5 km of which about 60% is in tunnel. The new section is planned to have 5–6 stations. The preliminary estimate for the investment costs is 700 MEUR that will be covered by the three municipalities and the state. The schedule of the project is dependent on the development of the area but it is estimated that the construction is going to start in 2016 earliest.

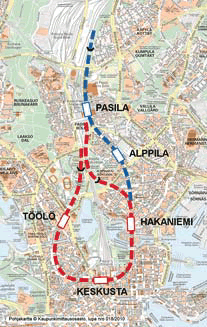

Commuter rail loop Pisara (Droplet) under Helsinki CBD

The rail yard of the Helsinki Main Railway Station is functioning at the limits of its capacity. No commuter or long distance traffic is possible to be increased. A solution for the capacity problem is a new commuter rail loop, Pisara, under the center of Helsinki. New stations are going to increase the level of service for passengers as well.

The rail yard of the Helsinki Main Railway Station is functioning at the limits of its capacity. No commuter or long distance traffic is possible to be increased. A solution for the capacity problem is a new commuter rail loop, Pisara, under the center of Helsinki. New stations are going to increase the level of service for passengers as well.

Currently, general planning and environmental impact assessment are under preparation by the Finnish Transport Agency and the City of Helsinki. The length of the shortest loop is about 8 km of which about 6 km is in tunnel. There is going to be 3 stations in the shortest loop: Töölö, CBD and Hakaniemi with the latter two having exchange connections to the metro. There is no cost estimate based on the existing plans for the project, yet, but it is assumed that the investment costs fall between 700–1,000 MEUR.

If the planning of the project is decided to be continued immediately after this ongoing planning phase and the project finds the necessary financing it is possible that Pisara loop could be in operation by 2020.

Helsinki Airport long distance rail connection

A preliminary study on a new long distance rail connection via the Helsinki Airport has been completed by the Finnish Transport Agency. The new rail connection between Pasila and Kerava via the airport would be in tunnel for almost its entire 30 km length. The connection is going to be constructed for mainly the national rail traffic but there will be some room for a few commuter trains, too. Between Pasila and Kerava there is going to be only one station at the airport with good interchange with the Ring Rail under construction phase in Vantaa.

The new rail connection enables a direct train service from the rest of the Finland and from the Helsinki center to the airport. In addition, it gives considerable amount of required room for more commuter and freight trains on the northern main railway. It has been evaluated that the project’s cost benefit ratio is over 1.

The Airport Rail Connection is scheduled for the period of 2021–2035 in the Regional Transportation System Plan. The cost estimate is 1,000 MEUR.

Pasila Metro

There is also a plan to extend metro from Kamppi to Pasila with 2–3 station in between. The project is dependent on the possible continuation from Pasila. The cost estimate is 330–370 MEUR depending on the number of stations. In the Regional Transportation System Plan the project is scheduled for the period after 2050.

Hakamäentie extensions

The transverse arterial in the northern Inner City, Hakamäentie, was improved 2010 including a short tunnel mentioned in the beginning. There are still two sections missing from the original plan between Turunväylä and Lahdenväylä. The missing western tunnel would take the through traffic away from local street network between Vihdintie and Turunväylä. The eastern tunnel would do the same to Koskelantie. In addition, the eastern tunnel would include a tunnel connection to the Kalasatama project area and further to the center of Helsinki.

The cost estimate for the western tunnel section is 180 MEUR and for the eastern tunnel sections 190 MEUR. The new tunnel sections are scheduled for the period 2021–2035 in the Regional Transportation System Plan.

Central Tunnel

The main objective of the Central Tunnel between Länsiväylä and Sörnäisten rantatie is to remove the through traffic from the streets of the CBD of Helsinki and feed the underground parking garages. Additionally, it would make it possible to enlarge the pedestrian areas in the CBD as well as make public transport work better in the CBD streets.

The main objective of the Central Tunnel between Länsiväylä and Sörnäisten rantatie is to remove the through traffic from the streets of the CBD of Helsinki and feed the underground parking garages. Additionally, it would make it possible to enlarge the pedestrian areas in the CBD as well as make public transport work better in the CBD streets.

The cost estimate of the 3.3 km long tunnel (the short alternative) is 525 MEUR. The Central Tunnel is included in the Master Plan of Helsinki as well as in the Underground Master Plan approved by the City Council just recently. However, the detailed planning of the tunnel has been stopped by the City Board and there exists no decision to construct it.

These upcoming projects illustrate the worldwide trend to increasing use of tunnels for environmental and energy benefits, as well as for infrastructure development in populated areas. Finland, like many other countries, expects to see increased use of tunnels in the future.

References

/1/ (Rinne, M., 2011). Preface, in Rock – Sound of Countless Opportunities, MTR, Helsinki. 136 p. Back ->

/2/ (Kivilaakso, E., 2011). Underground master plan of Helsinki, in Rock – Sound of Countless Opportunities, MTR, Helsinki. 136 p. Back ->

/3/ (Roinisto, J., 2011). Managing the environmental impact of an underground construction site, in Rock – Sound of Countless Opportunities, MTR, Helsinki. 136 p. Back ->

/4/ (Malmlund, H. and Pöllä, J., 2011). Central service tunnel – the main artery for improving the future center of Helsinki, in Rock – Sound of Countless Opportunities, MTR, Helsinki. 136 p. Back ->

/5/ (Palonen, E., 2011). Underground repository facility for nuclear waste – underground characterization and research facility ONKALO, in Rock – Sound of Countless Opportunities, MTR, Helsinki. 136 p. Back ->

/6/ (Poutanen, O-P., 2011). More traffic goes underground in Helsinki, in Rock – Sound of Countless Opportunities, MTR, Helsinki. 136 p. Back ->