Mr. Benoit de Rivaz

E-mail: benoit.derivaz@bekaert.com

Web: www.bekaert.com/underground

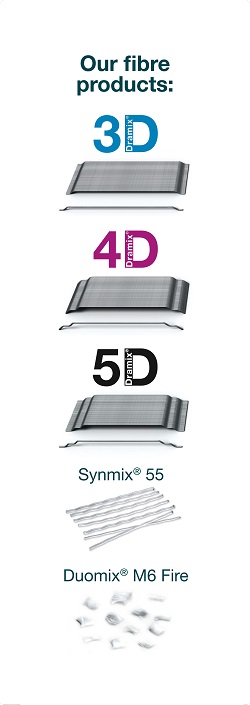

Our wide range of fibres give you the support your tunneling and mining project needs. Depending on the application, we have the right fibre for you at the right price.

Our Dramix® 3D fibres are at their best in shotcrete applications for first lining and temporary support. The Dramix® 4D product range is ideal for final lining of tunnels or shafts, either to be used in spray concrete linings or precast segments. Dramix® 5D offers superior results in final lining cast in-situ. Synmix® fibres are macro-synthetic fibres and can be used for temporary support in mining.

To complete our portfolio, we also offer micro-synthetic fibres called Duomix® M6 Fire that increase the fire resistance of concrete.

Bekaert is your global partner for smart fibre reinforcement of your tunnelling and mining project.

https://lnkd.in/dzsWAU9