Mr. Liu Yong

Deputy General Manager of the Overseas Department

No.88 Dongqi Road,

National Economic & Technical Development Zone

Changsha, Hunan, China

Postcode: 410100

Fax: + 86 731 8407 1800

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Web: en.crchi.com

Who we are

Founded in 2007, China Railway Construction Heavy Industry Corporation Limited (CRCHI) is a member of China Railway Construction Corporation Limited (CRCC). In 2022, CRCC is ranked No.39 of Global Fortune 500. We are a large professional enterprise focusing on the research, design, manufacture, and service of underground engineering equipment and rail transit system.

What Do We Do

CRCHI has been focusing on design, and manufacture of non-standardized, customized high-end equipment. It has created three mature industrial sections, which are rail track system, tunnel boring machine and drilling & blasting equipment, and in recent years stepped into new industry sections such as new rail transit system, agricultural machine, green building materials construction equipment, mining construction equipment, new construction materials etc. The company is a total solution provider for intelligent cluster systems of underground engineering equipment.

Our Mission

CRCHI is committed to becoming the world's leading underground engineering equipment and rail transit system provider. Based on the know-how, expertise and experience, CRCHI is at the forefront to promote the effectiveness and quality of underground construction, to reduce the cost and minimize the impact to environment and in the end to make our society and the world better, smarter and more sustainable.

Application cases

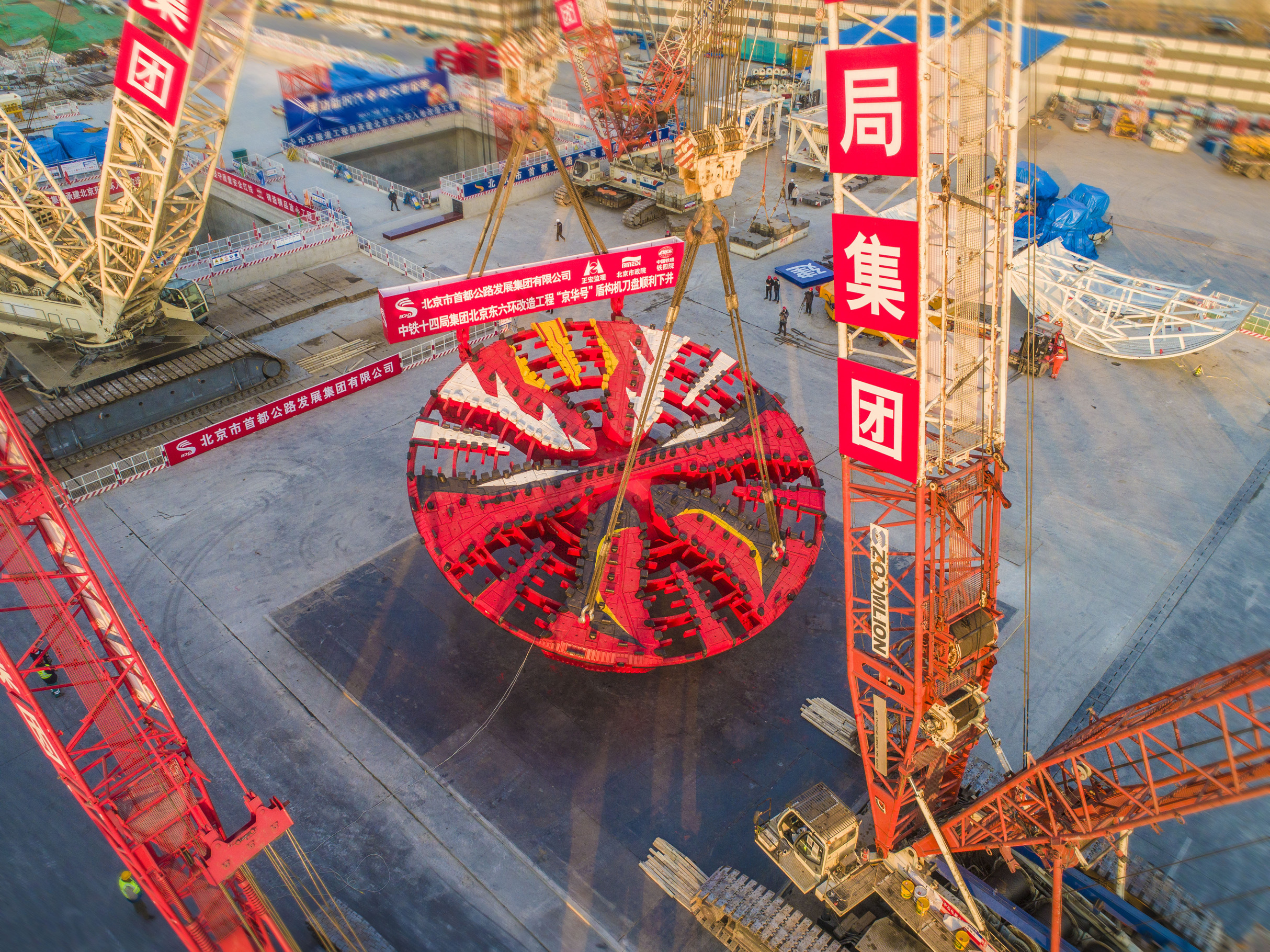

|

.jpg) |

|

| Φ16.07m slurry TBM applied in Beijing East 6th Ring Road Tunnel, China. Max. monthly advance rate 542 meters was achieved. | Φ12.19 m slurry TBM applied in Mumbai coastal road tunnel. Max. monthly advance rate 456.72 meters was achieved. | Φ12.74 m EPB shield TBM applied in Chengdu Railway Tunnel, China. Max. monthly advance 406.8 meters was achieved. |